An O-ring is a type of mechanical gasket used primarily in static applications to provide reliable sealing. Vulcanizing an O-ring makes it impermeable by liquids and gases, further extending its potential list of applications. At Arizona Sealing Devices, we carefully consider user requirements and application details to identify the ideal sealing solution for every client. To browse our solutions, please view AZ Seal’s catalog.

Overview of Vulcanized O-Rings

Generally speaking, vulcanized O-rings provide an ideal selection for static sealing. This is especially true in applications unsuitable for molded O-rings, such as those with oversized or non-standard measurements. Vulcanized O-rings are also viable when only a few pieces are needed, or when a customer needs an O-ring as quickly as possible and cannot wait the standard lead time for molded production.

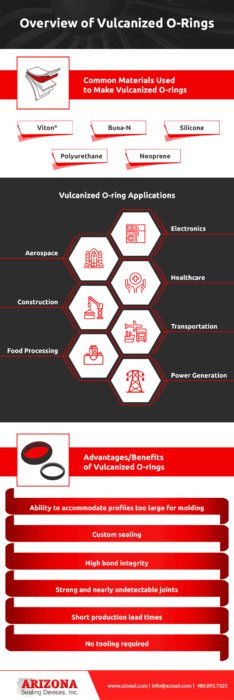

When selecting a vulcanized O-ring for your next job, there are a few qualities to consider. These include the type of rubber used, the color, the durometer, the cross-section, and the cord thickness. Common materials used to make vulcanized O-rings include:

- Viton®

- Buna-N

- Silicone

- Polyurethane

- Neoprene

The cut length of a vulcanized O-ring is calculated based on the desired diameter. There are two different cut angles to choose from:

- The butt cut is a default 90-degree cut, where the cord gets cut straight from top to bottom on the ring itself.

- A bevel cut, also known as a skive cut, occurs at a 45-degree angle. This cut ensures that more of the material’s surface area remains in contact at the joint to provide a stronger seal.

Advantages and Applications of Vulcanized O-Rings

All told, vulcanized O-rings offer a wide range of benefits. Some of these benefits may include:

- Ability to accommodate profiles too large for molding

- Custom sealing

- High bond integrity

- Strong and nearly undetectable joints

- Short production lead times

- No tooling required

Vulcanized O-rings are also quite versatile. These sealing solutions see frequent use in electronics, aerospace, healthcare, construction, transportation, food processing, power generation, and more.

FAQs on Vulcanized O-Rings

Are vulcanized O-rings right for my application?

Vulcanized O-rings can be used in any situation where a flange or lid must seal. The application itself doesn’t need to be round. If there are moving parts around the O-ring, then a vulcanized O-ring would not be an ideal solution.

How do you inspect a vulcanized joint?

First, locate the splice joint on the vulcanized O-ring. Using your fingers, give it a slight twist in either direction. Do so gently, or the O-ring may break. Also avoid bending the O-ring at the joint to avoid breakage. Provided that the vulcanized O-ring passes this “twist and tug” test, it is safe for installation or continued use.

Vulcanized O-Rings From Arizona Sealing Devices

Arizona Sealing Devices can provide the sealing solutions you need. Whether you’re looking for vulcanized O-rings, spliced O-rings, or another gasket or sealing solution, we will provide what you need as quickly and efficiently as possible.

To find out more information about vulcanized O-rings, please contact Arizona Sealing Devices today.