Since 1989, Arizona Sealing Devices has delivered high-quality seals for customers across a wide range of industries. Our knowledgeable team is dedicated to providing exceptional service, carefully curating and developing products designed to address the unique needs of each application.

In addition to O-rings, caps, plugs, and kits, our team carries an extensive collection of standard and custom die cut gaskets in a range of sizes, shapes, and configurations.

Our Die Cut Gaskets

Our team assists customers in selecting and designing the optimal sealing device for every application. Through close collaboration with our in-house experts, we consistently deliver products on time and on budget, transforming one-time buyers into lifelong customers.

Arizona Sealing Devices specializes in creating and distributing standard and custom die cut gaskets. We offer a variety of cutting methods to achieve the specifications required for any job. These die cutting approaches include:

- High-speed die cutting. Used to cut moderate-volume small, thin gaskets; can kiss-cut parts with an adhesive layer.

- Continuous feed CNC gasket die cutting. Used for high-volume production of mid-to-large-sized gaskets.

- Beam press, manual, and traveling head. Used for low-volume production of mid-to-large sized gaskets.

- Clicker press. Utilized for low-volumes for small to mid-sized gaskets.

- Knife slitting. Used in the production of gasket tape or strip rolls of material.

Die cut gaskets can be fabricated from a wide variety of material formulations and grades. These include:

- Rubber

- Rubber molding compounds

- Open- and closed-cell sponge rubber

- Compressed non-asbestos

- Cork

- Electrical insulation

- EMI/RFI shielding

- Fiber

- Foam

- Felt

- Graphite

- Plastics

- High-temperature materials

What is a Die Cut Gasket?

Die cut gaskets are mechanical seals that fill the gap between two surfaces when compressed. They help close the space between irregular surfaces, prevent leaks, and protect critical parts from damaging chemical, electrical, environmental, and physical forces.

These devices have essential functions across broad industries and applications. Examples include:

- Agriculture. They are used extensively in machinery like tractors, combines, and harvesters to form chemical, environmental, and pressure resistant closures.

- Automotive. Die cut gaskets close the gaps between stationary and moving parts to prevent lubricant from leaking into cavities.

- Aviation. Die cut gaskets withstand high speeds, extreme temperatures, and corrosive fluids in wings, windows, and other vital aviation parts.

- Military. They provide seals and insulation for vehicles and electronics exposed to harsh military environments.

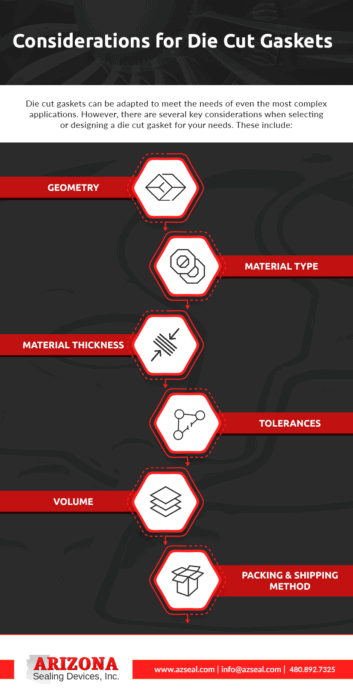

Considerations for Die Cut Gaskets

Die cut gaskets can be adapted to meet the needs of even the most complex applications. However, there are several key considerations when selecting or designing a die cut gasket for your needs. These include:

- Geometry. Die cutting is not appropriate for materials with thin walls.

- Material type. Many materials are prone to deformities, environmental susceptibility, etc., making them unsuitable for some applications. Temperature, pressure, media, and UV/ozone exposure should be considered.

- Material thickness. The density and thickness of the selected material will impact how and if it can be effectively die cut.

- Tolerances. Generally made from flexible materials, die cut gaskets require looser tolerances than stiff materials. Parts that necessitate tight tolerances should be cut using alternative methods.

- Volume. Small-, mid-, and large-volume runs are best suited to different die-cutting methods. For example, high-volume production volumes are best suited for CNC gasket die cutting.

- Packing and shipping method. Depending on run volume, a review of future packing requirements can drive cost savings when making a gasket selection.

Die Cut Gaskets From Arizona Sealing Services

Die cut gaskets play a critical role in the function of machine parts in major industries like agriculture, automotive, aviation, military, and more. With more than 30 years of experience and numerous options for material, size, shape, and configuration, Arizona Sealing Devices can guide customers through selecting or designing the optimal die cut gasket for any job. For more information about our die cut gaskets, contact us or request a quote today.