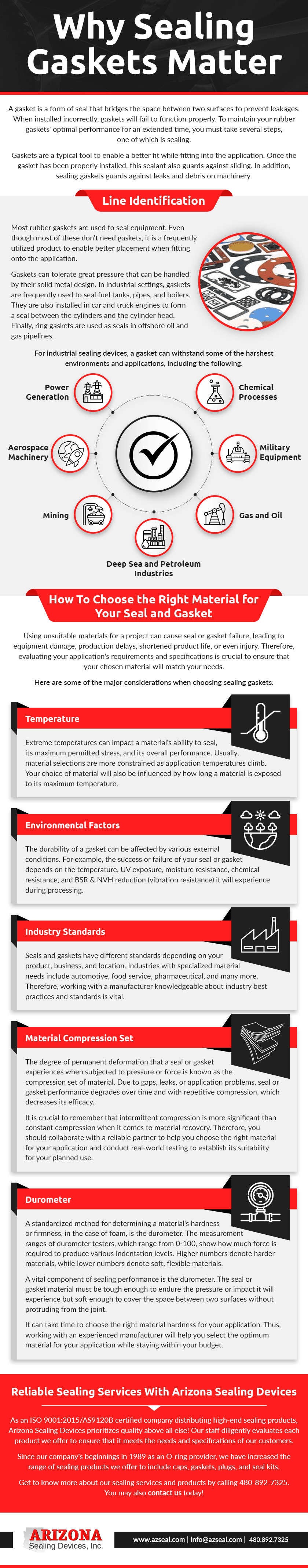

Why Sealing Gaskets Matter

A gasket is a form of seal that bridges the space between two surfaces to prevent leakages. When installed incorrectly, gaskets will fail to function properly. To maintain your rubber gaskets’ optimal performance for an extended time, you must take several steps, one of which is sealing.

Gaskets are a typical tool to enable a better fit while fitting into the application. Once the gasket has been properly installed, this sealant also guards against sliding. In addition, sealing gaskets guards against leaks and debris on machinery.

What Is a Gasket?

Most rubber gaskets are used to seal equipment. Even though most of these don’t need gaskets, it is a frequently utilized product to enable better placement when fitting onto the application.

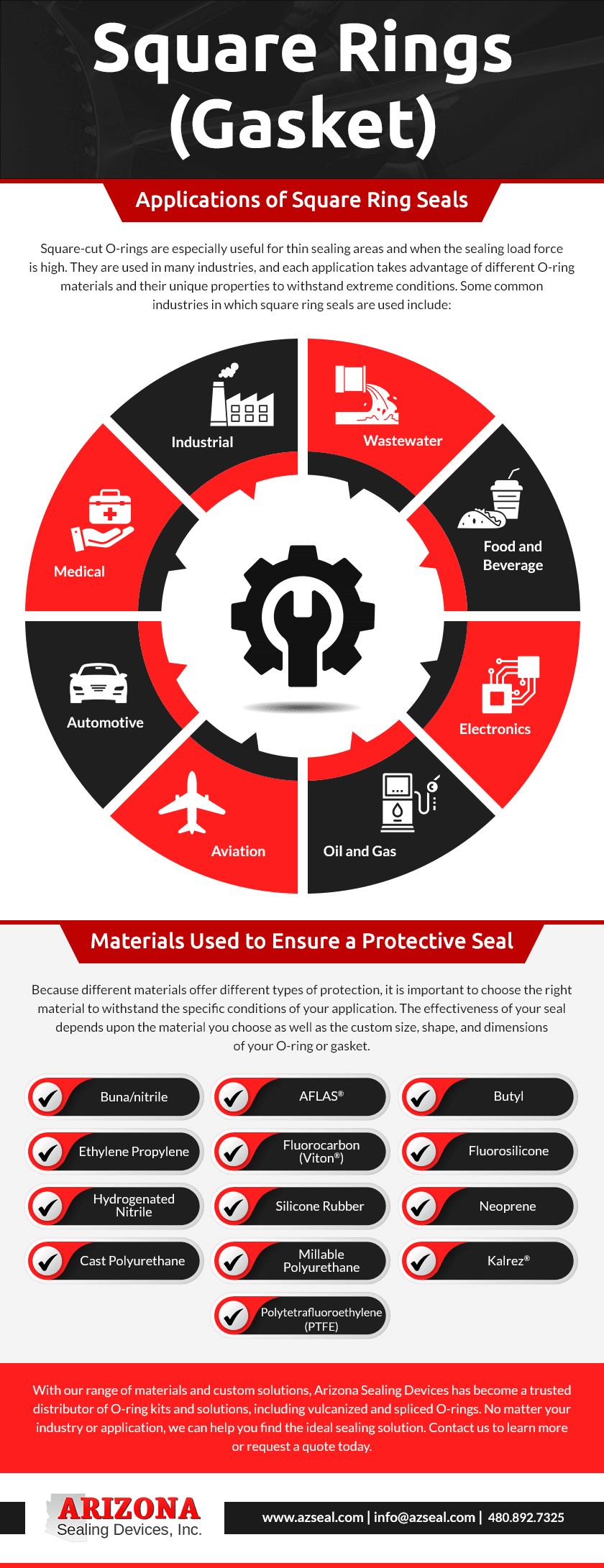

Gaskets can tolerate great pressure that can be handled by their solid metal design. In industrial settings, gaskets are frequently used to seal fuel tanks, pipes, and boilers. They are also installed in car and truck engines to form a seal between the cylinders and the cylinder head. Finally, ring gaskets are used as seals in offshore oil and gas pipelines.

For industrial sealing devices, a gasket can withstand some of the harshest environments and applications, including the following:

- Chemical processes

- Power generation

- Deep sea and petroleum industries

- Gas and oil

- Mining

- Military equipment

- Aerospace machinery

How To Choose the Right Material for Your Seal and Gasket

Using unsuitable materials for a project can cause seal or gasket failure, leading to equipment damage, production delays, shortened product life, or even injury. Therefore, evaluating your application’s requirements and specifications is crucial to ensure that your chosen material will match your needs.

Here are some of the major considerations when choosing sealing gaskets:

Temperature

Extreme temperatures can impact a material’s ability to seal, its maximum permitted stress, and its overall performance. Usually, material selections are more constrained as application temperatures climb. Your choice of material will also be influenced by how long a material is exposed to its maximum temperature.

Environmental Factors

The durability of a gasket can be affected by various external conditions. For example, the success or failure of your seal or gasket depends on the temperature, UV exposure, moisture resistance, chemical resistance, and BSR & NVH reduction (vibration resistance) it will experience during processing.

Industry Standards

Seals and gaskets have different standards depending on your product, business, and location. Industries with specialized material needs include automotive, food service, pharmaceutical, and many more. Therefore, working with a manufacturer knowledgeable about industry best practices and standards is vital.

Material Compression Set

The degree of permanent deformation that a seal or gasket experiences when subjected to pressure or force is known as the compression set of material. Due to gaps, leaks, or application problems, seal or gasket performance degrades over time and with repetitive compression, which decreases its efficacy.

It is crucial to remember that intermittent compression is more significant than constant compression when it comes to material recovery. Therefore, you should collaborate with a reliable partner to help you choose the right material for your application and conduct real-world testing to establish its suitability for your planned use.

Durometer

A standardized method for determining a material’s hardness or firmness, in the case of foam, is the durometer. The measurement ranges of durometer testers, which range from 0-100, show how much force is required to produce various indentation levels. Higher numbers denote harder materials, while lower numbers denote soft, flexible materials.

A vital component of sealing performance is the durometer. The seal or gasket material must be tough enough to endure the pressure or impact it will experience but soft enough to cover the space between two surfaces without protruding from the joint.

It can take time to choose the right material hardness for your application. Thus, working with an experienced manufacturer will help you select the optimum material for your application while staying within your budget.

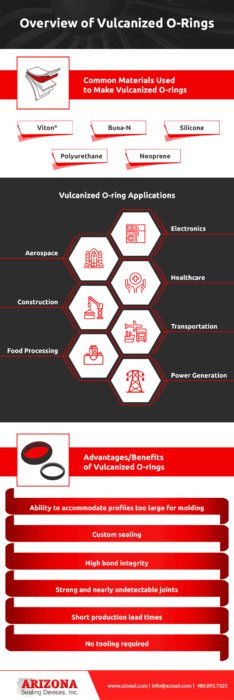

Reliable Sealing Services With Arizona Sealing Devices

As an ISO 9001:2015/AS9120B certified company distributing high-end sealing products, Arizona Sealing Devices prioritizes quality above all else! Our staff diligently evaluates each product we offer to ensure that it meets the needs and specifications of our customers.

Since our company’s beginnings in 1989 as an O-ring provider, we have increased the range of sealing products we offer to include caps, gaskets, plugs, and seal kits.

Get to know more about our sealing services and products by calling 480-892-7325. You may also contact us today!

Viton is a synthetic rubber elastomer that can be easily molded or extruded into precise shapes and forms for a wide variety of sealing applications. It typically comes in standard brown and black colors. The material has a hardness range of 50-95 on the durometer hardness scale, with a typical range of 70-75 Shore A. Viton is also inert and retains its properties at temperatures ranging from -20°F to 400°F.

Viton is a synthetic rubber elastomer that can be easily molded or extruded into precise shapes and forms for a wide variety of sealing applications. It typically comes in standard brown and black colors. The material has a hardness range of 50-95 on the durometer hardness scale, with a typical range of 70-75 Shore A. Viton is also inert and retains its properties at temperatures ranging from -20°F to 400°F. Chemical Properties

Chemical Properties

Silicone is an elastomer that remains stable, flexible, and non-reactive in extreme conditions, making it ideal for seals, gaskets, and O-rings. O-rings are molded products placed between two mechanical parts to create a tight seal for preventing fluid or gas leakage and keeping out contaminants. Choosing a silicone O-ring provides greater flexibility and performance for a wide variety of applications. With a range of properties and compositions available, you can easily customize your silicone O-rings for any implementation. This could include

Silicone is an elastomer that remains stable, flexible, and non-reactive in extreme conditions, making it ideal for seals, gaskets, and O-rings. O-rings are molded products placed between two mechanical parts to create a tight seal for preventing fluid or gas leakage and keeping out contaminants. Choosing a silicone O-ring provides greater flexibility and performance for a wide variety of applications. With a range of properties and compositions available, you can easily customize your silicone O-rings for any implementation. This could include  The properties of silicone O-rings allow them to be used across many industries and applications, including but not limited to:

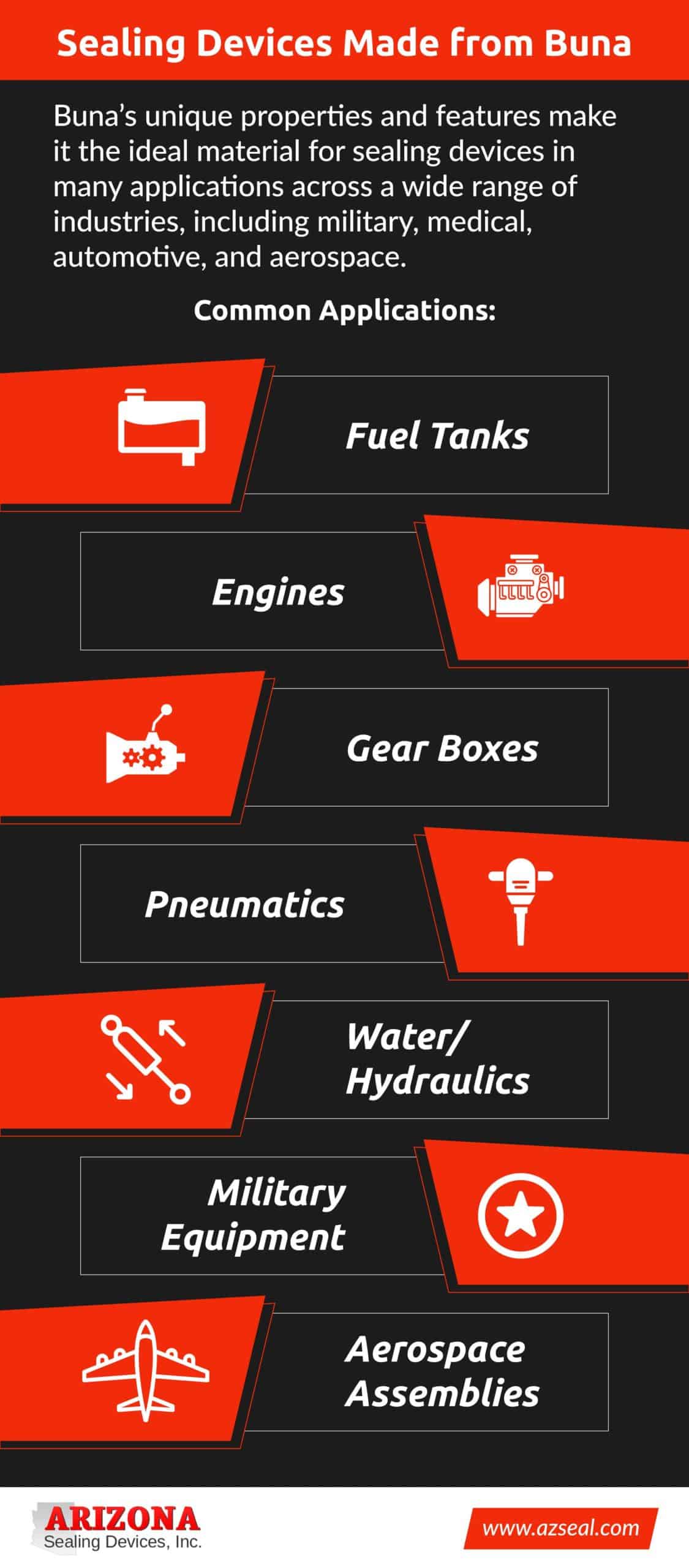

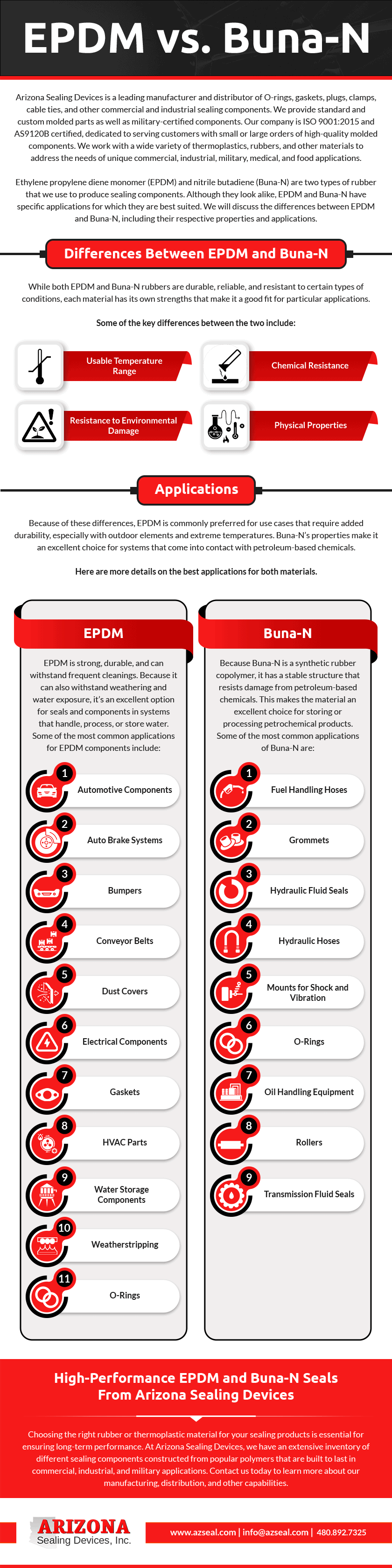

The properties of silicone O-rings allow them to be used across many industries and applications, including but not limited to: Buna offers many unique properties; making it the sealing industry’s most commonly used material. It is a durable, versatile elastomer that’s typically black in color and resistant to various chemicals, including fuel, oil, diluted acids, alkaline, mineral, vegetable oils, and more. Buna is resistant to abrasion, has a low compression set, and has a high tensile strength ranging from 200 to 3000 psi with 300% elongation at break.

Buna offers many unique properties; making it the sealing industry’s most commonly used material. It is a durable, versatile elastomer that’s typically black in color and resistant to various chemicals, including fuel, oil, diluted acids, alkaline, mineral, vegetable oils, and more. Buna is resistant to abrasion, has a low compression set, and has a high tensile strength ranging from 200 to 3000 psi with 300% elongation at break.