Arizona Sealing Devices was founded in 1989 as an O-ring supplier. Today, our wide selection of high-quality products includes square rings, gaskets, seals, plugs, and more. Browse our extensive inventory in our online catalog. We’re committed to helping you find the best sealing solution for your application.

Square O-Rings, Gaskets, and Seals

As a leading distributor of standard and custom gaskets and other sealing solutions, we have a wide range of products to choose from.

- O-Rings: The traditional round O-ring is versatile and reliable, sealing in any direction with little compressive force. Square O-rings have a square cross-section, which allows for a tighter seal on all surfaces, including uneven or irregular surfaces. The quad O-ring, also called an X-ring, features a four-lobed design to provide twice the sealing surface of a round O-ring.

- Gaskets: Made of a variety of materials — including felt, silicone, neoprene, and more — gaskets create a mechanical seal between irregular surfaces. They’re trusted in mission-critical applications in the aviation, military, agricultural, and automotive industries.

- Seals: Among our many sealing solutions, we offer Viton, a synthetic rubber elastomer that is easily molded into precise shapes ideal for a variety of applications. Viton offers excellent heat, flame, acid, weather, ozone, and oil resistance.

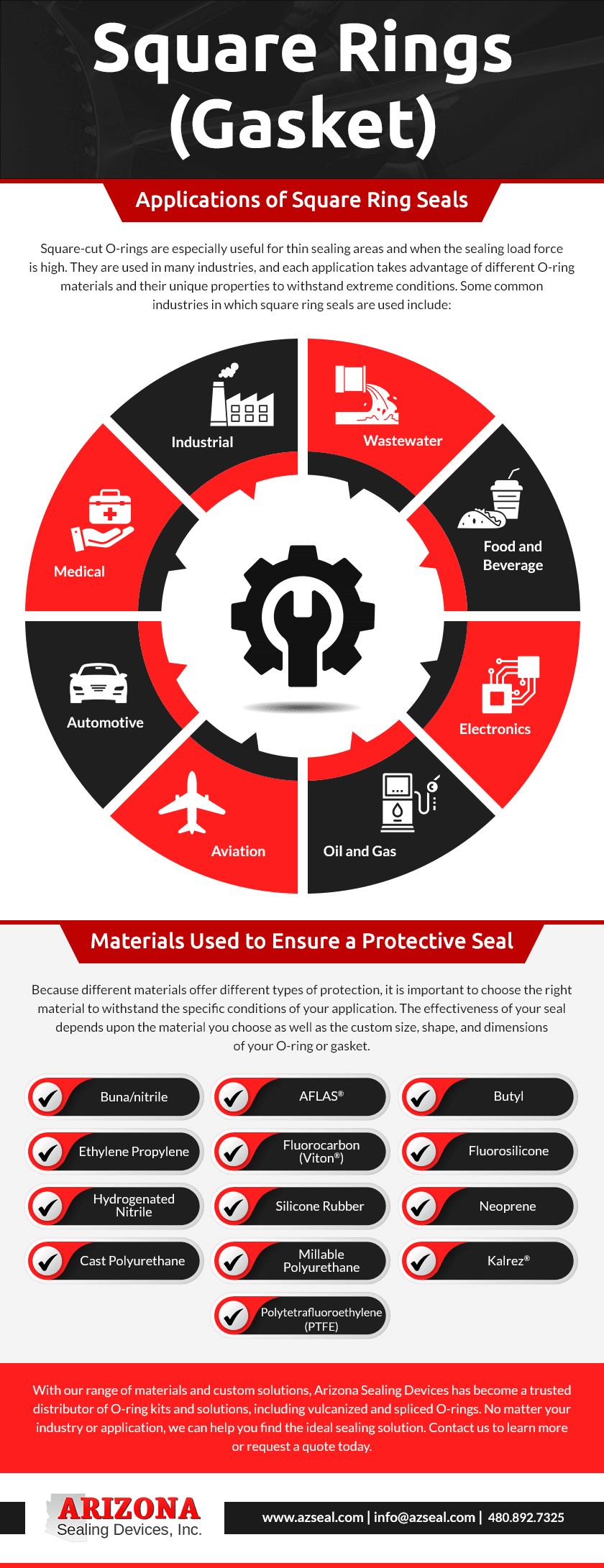

Applications of Square Ring Seals

Square-cut O-rings are especially useful for thin sealing areas and when the sealing load force is high. They are used in many industries, and each application takes advantage of different O-ring materials and their unique properties to withstand extreme conditions. Some common industries in which square ring seals are used include:

- Wastewater: O-rings in wastewater applications must be corrosion- and chemical-resistant to withstand the harsh chemicals and materials to which they are exposed.

- Food and Beverage: Food and beverage O-rings must be nontoxic, hypoallergenic, bacteria-resistant, chemical-resistant, and temperature-resistant to meet FDA guidelines and keep products safe for consumption.

- Electronics: Sealing components protect electronics from environmental conditions and electromagnetic and radio frequency interferences.

- Oil and Gas: Oil and gas applications require chemical-, temperature-, and abrasion-resistant o-rings to ensure safe rig operations.

- Aviation: O-rings are often used in electrical components and fuel systems due to their ability to withstand high speeds, drastic pressure changes, extreme temperature fluctuations, and fluid exposure.

- Automotive: Often used in braking systems and engines to prevent leakages and protect components against external elements.

- Medical: O-rings are imperative for any medical device that operates using valves, pumps, or cylinders. Medical O-rings must comply with FDA standards and be able to withstand extreme temperatures and frequent sanitizing.

- Industrial: The versatility of o-rings allows them to be used in hydraulic, pneumatic, static, and dynamic industrial processes to keep them functioning efficiently.

Materials Used to Ensure a Protective Seal

Because different materials offer different types of protection, it is important to choose the right material to withstand the specific conditions of your application. The effectiveness of your seal depends upon the material you choose as well as the custom size, shape, and dimensions of your O-ring or gasket.

- Buna/nitrile: High tensile strength, corrosion- and abrasion-resistant, one of the most common material choices for O-rings

- AFLAS®: Temperature and chemical resistant, common in oil, gas, aerospace, and industrial applications

- Butyl: Low permeability, excellent for vacuum sealing

- Ethylene propylene: Similar to butyl with better ozone and chemical resistance

- Fluorocarbon (Viton®): Common in high-temperature, high-exposure applications like engines and fuel handling systems, one of the best overall material choices available

- Fluorosilicone: Fuel resistant, temperature stable, common for aerospace fueling and static sealing

- Hydrogenated nitrile: Oil-resistant, corrosion-resistant, stronger than standard nitrile

- Silicone rubber: Temperature-resistant, medical-grade silicone is available, common for static sealing in extreme temperatures

- Neoprene: Chemical-resistant, temperature-resistant, high strength, common in refrigerator sealing

- Cast polyurethane: Abrasion-resistant, common in high-wear applications

- Millable polyurethane: Similar to cast polyurethane with lower tensile strength

- Kalrez®: Extremely chemical-resistant, common in oil and gas, chemical processing, and paint applications

- Polytetrafluoroethylene (PTFE): Chemical-resistant, temperature-resistant, requires care in installation because it has poor elastic memory at room temperature

With our range of materials and custom solutions, Arizona Sealing Devices has become a trusted distributor of O-ring kits and solutions, including vulcanized and spliced O-rings. No matter your industry or application, we can help you find the ideal sealing solution. Contact us to learn more or request a quote today.