O-rings are an essential component in many industrial manufacturing processes. These simple yet effective rubber rings provide a tight seal between two mating surfaces, allowing for the transfer of fluids or gases while preventing leaks. They have been used in aerospace, automotive, and medical applications since their invention by Danish engineer Neils Christensen in 1937.

O-rings offer superior sealing capabilities compared to traditional gaskets. Their versatility and cost-effectiveness make them an ideal choice for applications ranging from fuel lines to oil seals on engines. They can also be manufactured with different materials, making them one of the most widely used components across multiple industries today.

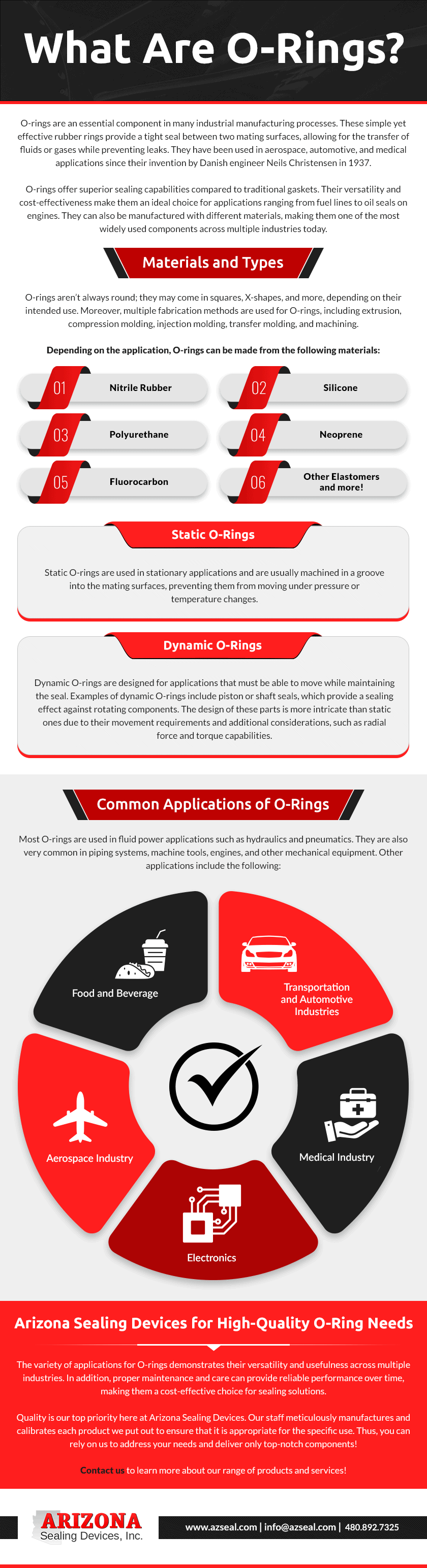

Materials and Types

O-rings aren’t always round; they may come in squares, X-shapes, and more, depending on their intended use. Moreover, multiple fabrication methods are used for O-rings, including extrusion, compression molding, injection molding, transfer molding, and machining.

Depending on the application, O-rings can be made from the following materials:

- Nitrile rubber

- Silicone

- Polyurethane

- Neoprene

- Fluorocarbon

- Other elastomers and more!

Static O-Rings

Static O-rings are used in stationary applications and are usually machined in a groove into the mating surfaces, preventing them from moving under pressure or temperature changes.

Dynamic O-Rings

Dynamic O-rings are designed for applications that must be able to move while maintaining the seal. Examples of dynamic O-rings include piston or shaft seals, which provide a sealing effect against rotating components. The design of these parts is more intricate than static ones due to their movement requirements and additional considerations, such as radial force and torque capabilities.

Common Applications of O-Rings

Most O-rings are used in fluid power applications such as hydraulics and pneumatics. They are also very common in piping systems, machine tools, engines, and other mechanical equipment. Other applications include the following:

Transportation and Automotive Industries

O-rings are ideal for sealing fluids such as motor oil and other liquid fuel systems, brake fluids, antifreeze, and more. Additionally, they can be used in the air intake and cooling systems to prevent leakage of air or coolant.

Medical Industry

O-rings are vital to medical device applications, such as oxygen tanks, fluid delivery systems, respiratory equipment, and more. Due to their resistance to extreme temperatures, chemicals, and gases, they provide a reliable seal even under highly hazardous conditions.

Electronics

Due to their small size and high strength, O-rings are often used in the electronics industry. They are applied as seals for circuit boards, switches, connectors, and other components to prevent moisture and dust from entering the devices.

Aerospace Industry

O-rings’ ability to withstand extreme temperatures makes them well-suited for various aerospace applications, such as fuel tanks, actuators, landing gear systems, hydraulics, oxygen regulators, cabin pressure control systems, and others.

Food and Beverage

O-rings are ideal for applications that require a tight seal, such as in soft drink dispensers, beer kegs, or chocolate enrober machines. They can also be found in bottle caps, faucets, and other food-related machinery.

Arizona Sealing Devices for High-Quality O-Ring Needs

The variety of applications for O-rings demonstrates their versatility and usefulness across multiple industries. In addition, proper maintenance and care can provide reliable performance over time, making them a cost-effective choice for sealing solutions.

Quality is our top priority here at Arizona Sealing Devices. Our staff meticulously manufactures and calibrates each product we put out to ensure that it is appropriate for the specific use. Thus, you can rely on us to address your needs and deliver only top-notch components!

Contact us to learn more about our range of products and services!