Arizona Sealing Devices is a leading manufacturer and distributor of O-rings, gaskets, plugs, clamps, cable ties, and other commercial and industrial sealing components. We provide standard and custom molded parts as well as military-certified components. Our company is ISO 9001:2015 and AS9120B certified, dedicated to serving customers with small or large orders of high-quality molded components. We work with a wide variety of thermoplastics, rubbers, and other materials to address the needs of unique commercial, industrial, military, medical, and food applications.

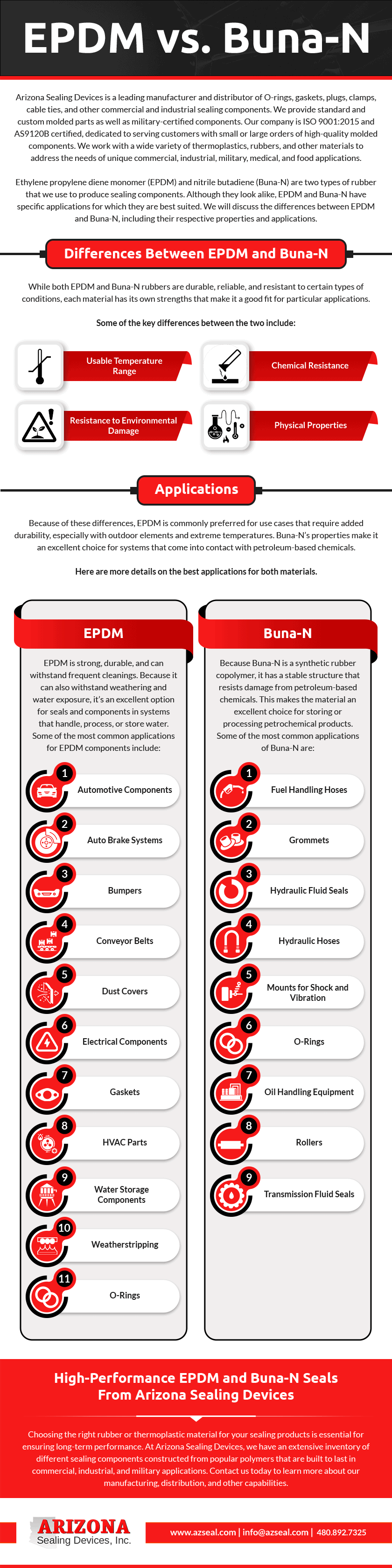

Ethylene propylene diene monomer (EPDM) and nitrile butadiene (Buna-N) are two types of rubber that we use to produce sealing components. Although they look alike, EPDM and Buna-N have specific applications for which they are best suited. We will discuss the differences between EPDM and Buna-N, including their respective properties and applications.

Differences Between EPDM and Buna-N

While both EPDM and Buna-N rubbers are durable, reliable, and resistant to certain types of conditions, each material has its own strengths that make it a good fit for particular applications. Some of the key differences between the two include:

- Usable temperature range: Buna-N offers a temperature range of -40 °C to 107 °C for most applications, including dairy and food processing operations. EPDM, on the other hand, has a temperature range between -48 °C and 135 °C, making it more applicable across a greater range of cold and heat settings, such as hot water and steam environments.

- Chemical resistance: EPDM is resistant to deionized water and acidic, alkaline, and alcohol substances used in common cleaning agents. However, EPDM can be easily damaged by exposure to petroleum-based chemicals. Buna-N offers high resistance to damage from petroleum-based fluids, but it can be damaged by exposure to acids and alkaline chemicals over time.

- Resistance to environmental damage: EPDM is well-regarded for its excellent resistance to weather, including ozone and UV light exposure. This makes it more resistant to aging, especially in outdoor and water-based applications. Buna-N is less resistant to ozone and generally should not be used in outdoor areas.

- Physical properties: Buna-N offers good physical properties, but EPDM is resistant to abrasion and offers high tensile strength.

Applications

Because of these differences, EPDM is commonly preferred for use cases that require added durability, especially with outdoor elements and extreme temperatures. Buna-N’s properties make it an excellent choice for systems that come into contact with petroleum-based chemicals. Here are more details on the best applications for both materials.

EPDM

EPDM is strong, durable, and can withstand frequent cleanings. Because it can also withstand weathering and water exposure, it’s an excellent option for seals and components in systems that handle, process, or store water. Some of the most common applications for EPDM components include:

- Automotive components

- Auto brake systems

- Bumpers

- Conveyor belts

- Dust covers

- Electrical components

- Gaskets

- HVAC parts

- Water storage components

- Weatherstripping

Buna-N

Because Buna-N is a synthetic rubber copolymer, it has a stable structure that resists damage from petroleum-based chemicals. This makes the material an excellent choice for storing or processing petrochemical products. Some of the most common applications of Buna-N are:

- Fuel handling hoses

- Grommets

- Hydraulic fluid seals

- Hydraulic hoses

- Mounts for shock and vibration

- O-rings

- Oil handling equipment

- Rollers

- Transmission fluid seals

High-Performance EPDM and Buna-N Seals From Arizona Sealing Devices

Choosing the right rubber or thermoplastic material for your sealing products is essential for ensuring long-term performance. At Arizona Sealing Devices, we have an extensive inventory of different sealing components constructed from popular polymers that are built to last in commercial, industrial, and military applications. Contact us today to learn more about our manufacturing, distribution, and other capabilities.