O-rings are a vital tool for ensuring the effective operation of numerous vehicles, appliances, and other everyday items. Proper O-ring installation creates a strong seal, allowing the product to function efficiently without leakage.

What is an O-Ring?

While they may seem simple, O-rings actually serve an important purpose. This round, often rubber ring helps to prevent leaks and product failures. They do this by creating a seal between parts, which stops air and fluid from moving around within the final product. O-rings are generally designed to be installed within a groove and then compressed. They come in a variety of different materials, which can make material selection an important consideration.

How to Install an O-Ring

Due to their vital function, it’s important to know exactly how to install an O-ring without damaging it. The first step to proper installation is to choose an appropriate lubricant and use it to lightly coat your O-ring.

Once you have properly lubricated the O-ring, you should make sure to cover any sharp edges on the parts that may come into contact with the O-ring. This helps prevent the O-ring from being damaged during the installation process. It’s also important to be cognizant of how much you stretch the O-ring during installation—it should stretch no more than 50%, and any stretching should be performed uniformly rather than just one side.

After you have successfully slid the O-ring onto the shaft, the final step is to ensure that the seal is not twisted inside the groove. If installing a backup O-ring, make sure to do it on the low pressure side of the system so that the high pressure will push the O-ring against the backup rather than away from it.

Tips for O-Ring Installation

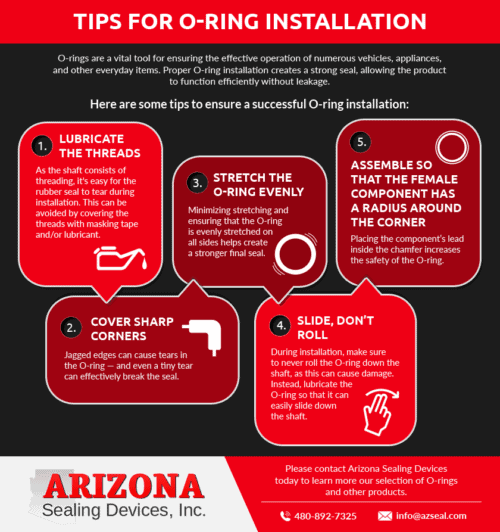

Here are some tips to ensure a successful O-ring installation:

- Lubricate the threads. As the shaft consists of threading, it’s easy for the rubber seal to tear during installation. This can be avoided by covering the threads with masking tape and/or lubricant.

- Cover sharp corners. Jagged edges can cause tears in the O-ring — and even a tiny tear can effectively break the seal.

- Stretch the O-ring evenly. Minimizing stretching and ensuring that the O-ring is evenly stretched on all sides helps create a stronger final seal.

- Slide, don’t roll. During installation, make sure to never roll the O-ring down the shaft, as this can cause damage. Instead, lubricate the O-ring so that it can easily slide down the shaft.

- Assemble so that the female component has a radius around the corner. Placing the component’s lead inside the chamfer increases the safety of the O-ring.

Using O-Ring Lubricants

Choosing the appropriate lubricant is a vital step in the proper installation of an O-ring. There are many common types of lubricants, including:

- Petroleum distillates

- Soap and water

- Solvents

- Ester based lubricants

While there are many choices, however, they are not all created equal. Certain types of lubricant will actively damage the O-ring or cause safety issues. Solvents, for example, are not a particularly effective lubricant. They can be flammable, pose health risks, and contain high VOCs.

Petroleum distillates are another common, but less than ideal choice, as they frequently cause rubber to dry out or swell. While soap and water may be safe, they are not especially effective. They may even reactivate when wet, which can significantly reduce the efficacy of the O-ring.

The best choice for O-ring lubricant is almost always an ester based product. This type of lubrication is safe for workers and environmentally friendly. It also drastically reduces friction and offers effective temporary lubrication during the installation process.

Partner With the Qualified Sealing Experts

Although O-rings are a fairly simple tool, they serve a vital function in a myriad of products. Understanding the fundamentals of how to properly install an O-ring can ensure that your project will be successful.

At Arizona Sealing Devices, we’ve been specializing in high-quality sealing devices since 1989. Our team of experts is well-versed in helping clients find the best solution for their unique needs. To learn more about our offerings, contact us or request your quote today.